Incision Decision

- - -

Overview

- - -

Plaque

- - -

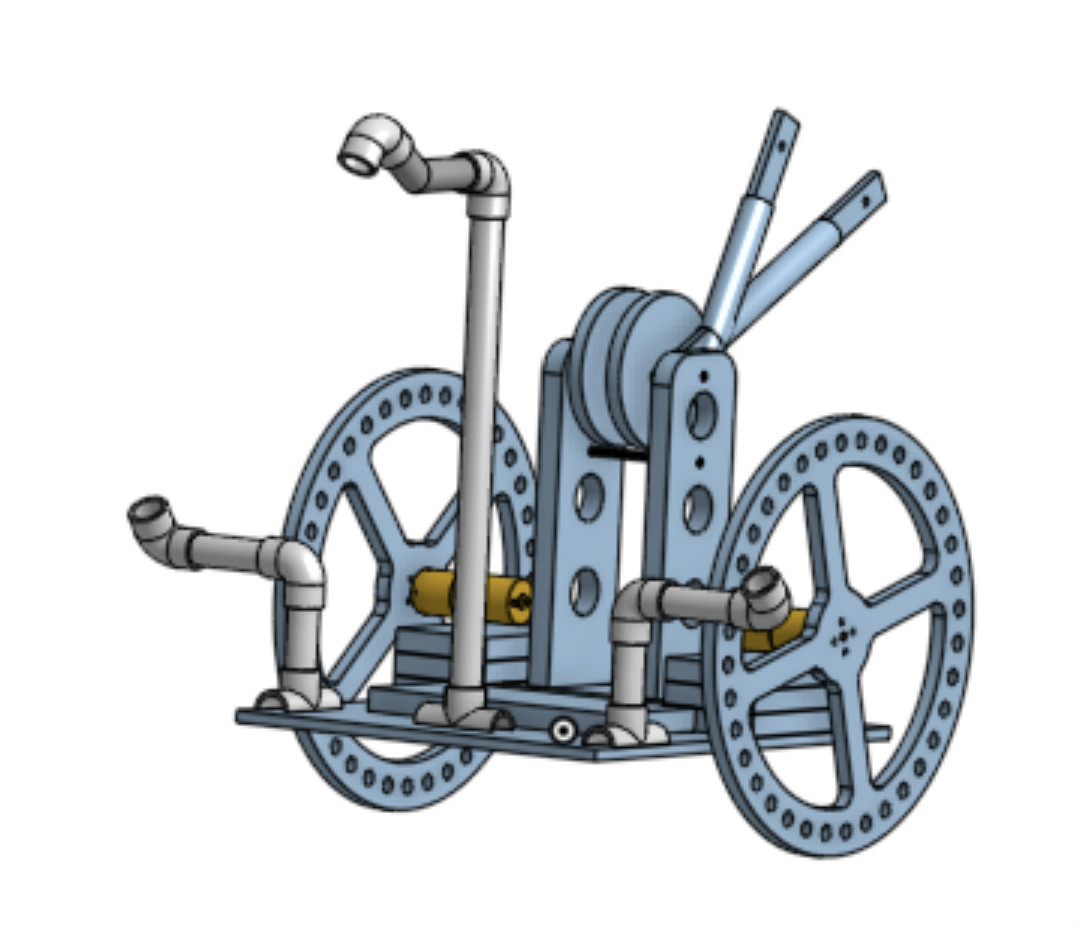

Base

- - -

Arm/Vein

Overview

Each subsystem created a list of different parameters in which they established their designs. A number of different considerations had to be taken into account for their design parameters due to a number of conflicting issues, one of the most integral being material cost. Each subsystem would engineer their individual prototypes out of any material and would then later constrain them to best fit the game requirements.

Plaque Collection Tool

- It is a modified cardboard box with a 45 degree slope on one side. It is approximately 6.5’’ by 9.5’’. The sides of the box come up 3.25’’. There is a 1’’ PVC pipe sticking up from the middle of the box with a PVC T on the top. Combined the PVC is 5.5’’ tall. On the 4-bar mechanism, there is a passive grabber responsible for keeping a hold of and, when ready, dispensing the entire box into the Biowaste container. The grabbing mechanism is made up of a 2’’ x 3’’ PVC sheet with two small .25’’ x 1.5’’ arms made of the same material. The arms can rotate around an axis and hold on to the PVC tube from the cardboard box via pressure from rubber bands. When the robot runs the cardboard box into a wall, the box will tip over, dispensing any game pieces (plaque or brain) into the Biowaste container.

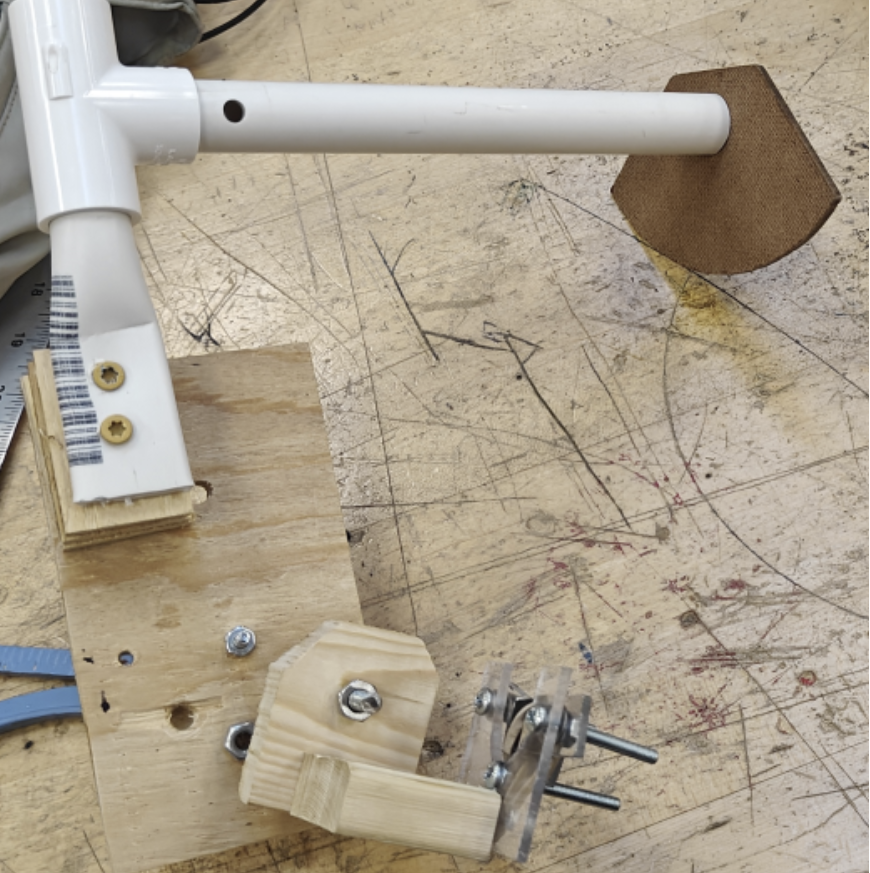

Removal Tool -

A tool that resembles the provided removal tool. This design has a flexible base made out of sheet pvc, and an angled scraper.

Base-

14” by 16” piece of wood that is responsible for the integration of subsystems, with 15” wheels mounted that are responsible for facilitating the motion of the robot. The base is sturdy and allows for other subsystems to operate with the space required to not interfere with the other systems. The base also possesses two drag points to limit tipping.

Vein Harvesting

Vein Removal -

Plastic C-shaped grabber that passively goes around the vein. A servo that is turned on its side is attached to the top of the C shaped grabber, which has a 4-5 inch curved piece of plastic attached to the servo horn and a copy of that piece of plastic is directly across to the side of the servo on the other edge of the grabber. They are connected by another piece of plastic which acts to make them move in unison as it closes over the opening of the grabber. When the vein is inside the c shaped grabber, the servo turns and closes the 2 attached 4-5 inch curved pieces of plastic over the opening of the grabber. Inside the grabber on the bottom surface that the vein rests there are 2 elongated thin surfaces that extend out the sides just an inch or 2 that acts as a guide to drop the vein into the keyhole.

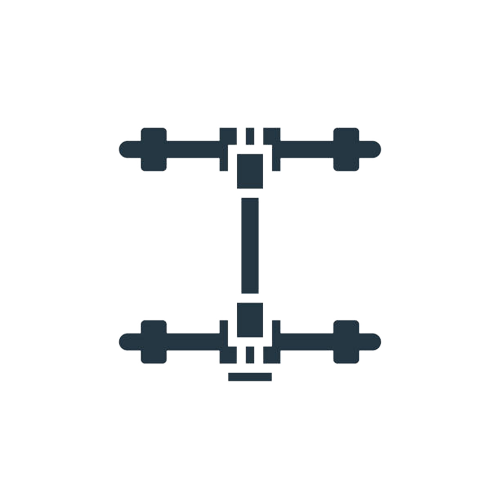

Arm

four-bar style lifting mechanism made of 1x4 wood and pvc that utilizes two lifting motors. The four bar also utilizes a plywood pitch wheel to gain more lifting power.

Jigsaw Surgical Solutions

Jigsaw Surgical Solutions